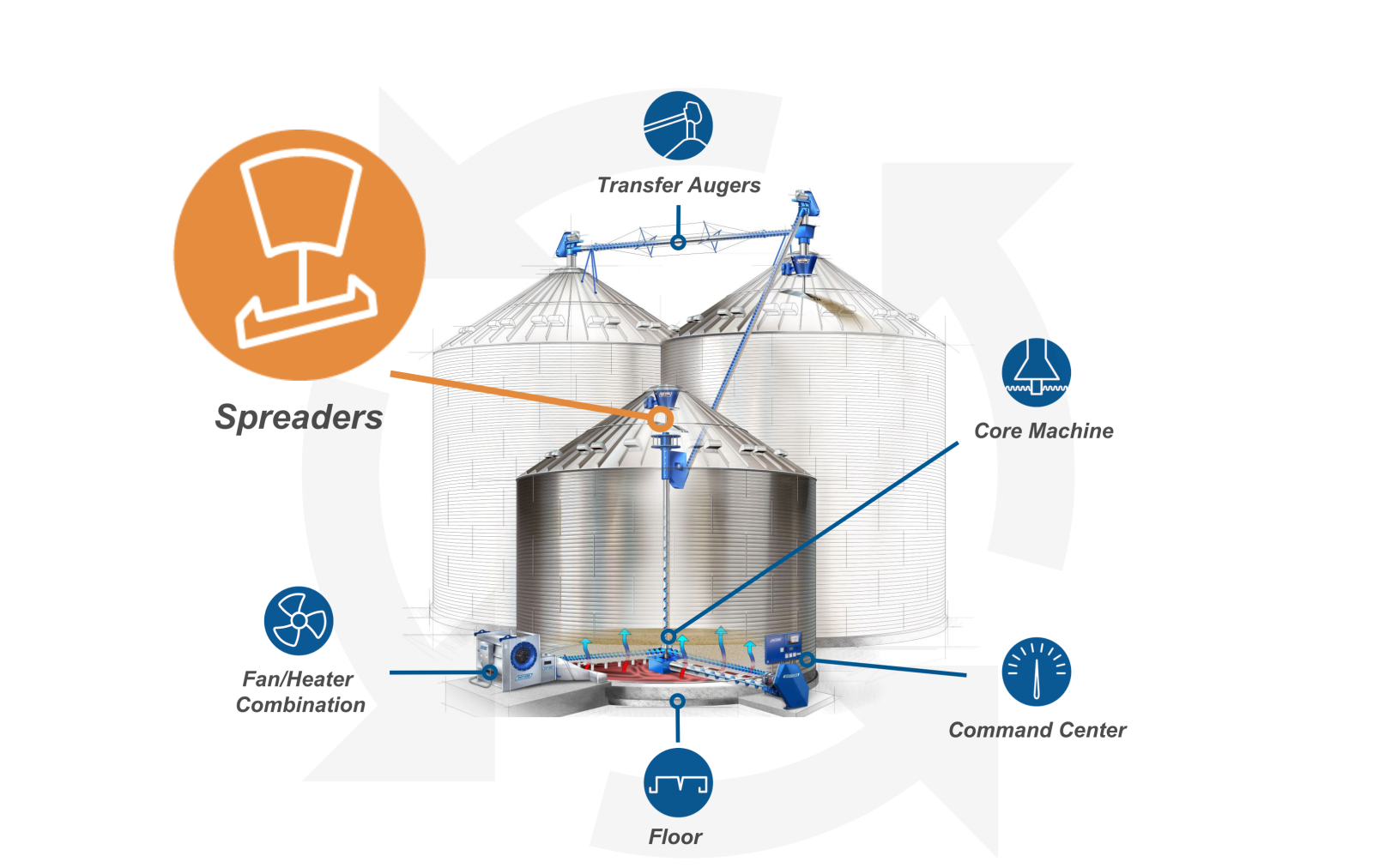

Grain Loading & Spreaders

True & Level Grain Loading for a Shivvers System

|

Shivvers Spreaders and grain loading equipment have been perfected to ensure true, level grain loading and are engineered with 5 key variables in mind:

- Uniform Drying Consistency

- Air Flow Optimization

- Drying Efficiency

- Maximized Capacity

- State-Of-The-Art Control

At Shivvers, we understand that the function of grain loading equipment isn’t just about evenly spreading grain - we perfected that decades ago.

It’s about providing the operator with control to make adjustments as crop conditions vary. It’s about manipulating grain depths to maximize efficiency. It’s about ensuring that grain is loaded at the optimum density to increase air flow and capacity. But above all, it’s about creating the most effective drying conditions to ensure a precise and consistently dried crop - maximizing your profit at the elevator.

|

|

Shivvers Level-Dry Grain Spreader

.jpg) Increasing drying capacities anywhere from 30-300%, the Shivvers Level-Dry grain spreader converts in-bin continuous flow dryers into ultra high-speed drying systems.

Increasing drying capacities anywhere from 30-300%, the Shivvers Level-Dry grain spreader converts in-bin continuous flow dryers into ultra high-speed drying systems.

Rather than mounting to the top of the bin, the Level-Dry is secured around a central pivot point inside the bin and can be raised or lowered to match your desired grain depth. As grain is loaded through the top of the bin, it is funneled through the Level-Dry’s hopper and spread outward via a leveling auger. The leveling auger rotates around a central pivot point, ensuring 360 degrees of evenly spread grain. The operator has the ability to adjust grain depths at any time during the loading process. Any dips or low spots in the grain are filed to give a smooth, uniform surface of wet grain after each pass.

The Shivvers Level-Dry’s revolutionary design is perfect for the operator looking for maximized capacities, unmatched efficiency, and unprecedented drying precision.

Shivvers Controlled Flow Spreader

Shivvers Controlled Flow Spreader

The Controlled Flow Spreader provides the ultimate in operator control while facilitating up to 6,000 bushel per hour filling capacities.

The Controlled Flow Spreader features a dual motor system, with one motor driving a diverter valve and the other to power the spreader pan’s rotation. Independent adjustments can be made from the ground to guide not only where grain falls on the spreader pan, but also the speed of the pans rotation.

The Controlled Flow Spreader is perfect for the operator with large operations, looking for from-the-ground precision filling control.

Shivvers Grain Hog Spreader

Shivvers Grain Hog Spreader

With filling capacities from 3,200-5,000 bushes per hour, Grain Hog Spreaders are the standard for Shivvers Performance Systems, providing a mechanically adjustable solution to distribute grain.

Grain Hog Spreaders are offered in various pan sizes and feature a single-speed motor, available in .5-1.5 HP options. Pan & motor combinations are offered to fit bin diameters from 24-42 feet and auger sizes from 8-12 inches. Additional adjustments can be made on the spreader itself, allowing the Grain Hog to be perfectly calibrated to fit your operation’s needs.

The Grain Hog Spreader is perfect for the operator looking for an economical option to distribute grain with the precision standards Shivvers is known for.

Grain Loading Options & Accessories

Select an option below for model specific details