System Components:

| With each system custom configured to meet the grower’s requirements, Shivvers Hemp Drying Systems are integrated into a grain silo, effectively turning the entire structure into a comprehensive dehydration solution. Depending on your operation’s capacity requirements, Shivvers Systems are available in 2 sizes with options to fit 24' & 36' silo diameters. A complete system can be broken down into the following 4 core components, each expertly designed & manufactured by Shivvers: | |

| Command Center Control Unit  Serving as the “brain” of the system, the Shivvers Command Center is a central computerized control unit that manages the drying process based off the operator’s pre-set specifications. Offering versatile temperature control options ranging from 90°F to as high as 140°F, the Command Center allows the operator to select their desired drying specifications. The Command Center then activates the dryer, warming air in the plenum created by the raised drying floor. The Command Center maintains constant communication with the heater throughout the drying process, making automatic adjustments to sustain the precise temperature specified by the operator. Serving as the “brain” of the system, the Shivvers Command Center is a central computerized control unit that manages the drying process based off the operator’s pre-set specifications. Offering versatile temperature control options ranging from 90°F to as high as 140°F, the Command Center allows the operator to select their desired drying specifications. The Command Center then activates the dryer, warming air in the plenum created by the raised drying floor. The Command Center maintains constant communication with the heater throughout the drying process, making automatic adjustments to sustain the precise temperature specified by the operator.

|

| Fan | Heater  The heat source and air movement force for the dehydration process, Shivvers Fan & Heater units have been perfected over decades to offer unrivaled fuel efficiency and optimized heating capabilities. Automatically controlled by the central Shivvers Command Center, Fan & Heater units feature a specially designed downstream burner with Shivvers Blue Flame Technology to maximize clean and uniform heating. With various Fan & Heater combinations available, expertly trained Shivvers Technicians will work with you to understand your operation’s size, fuel, power, & capacity needs to ensure the optimal combination for your operation. The heat source and air movement force for the dehydration process, Shivvers Fan & Heater units have been perfected over decades to offer unrivaled fuel efficiency and optimized heating capabilities. Automatically controlled by the central Shivvers Command Center, Fan & Heater units feature a specially designed downstream burner with Shivvers Blue Flame Technology to maximize clean and uniform heating. With various Fan & Heater combinations available, expertly trained Shivvers Technicians will work with you to understand your operation’s size, fuel, power, & capacity needs to ensure the optimal combination for your operation.

|

| Perforated Raised Drying Floor The foundation for a Shivvers System, Shivvers Channel-Lock Floors and Structural Steel Supports elevate the floor to provide a heating chamber where air is mixed to a uniform temperature. Strategically designed perforations in the flooring facilitate controlled air flow, allowing warmed drying air to rise up through the floor into the hemp drying zone. In addition to providing a heating plenum, the raised floor also creates an unloading chamber. Accessible by an exterior unloading door, integrated floor chutes allow dry hemp to be dropped directly into bags or onto a conveyor to be transported for bagging. |

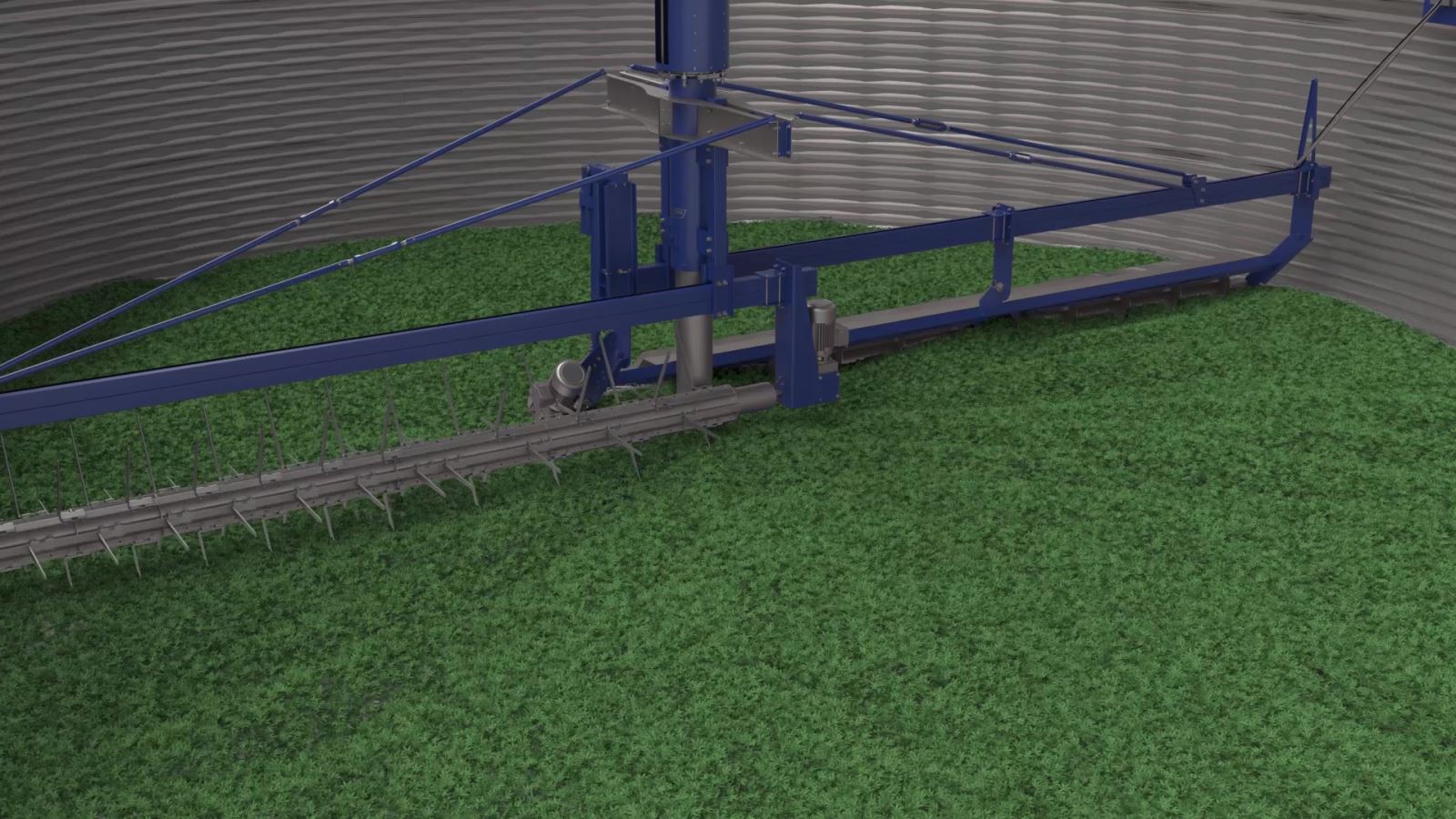

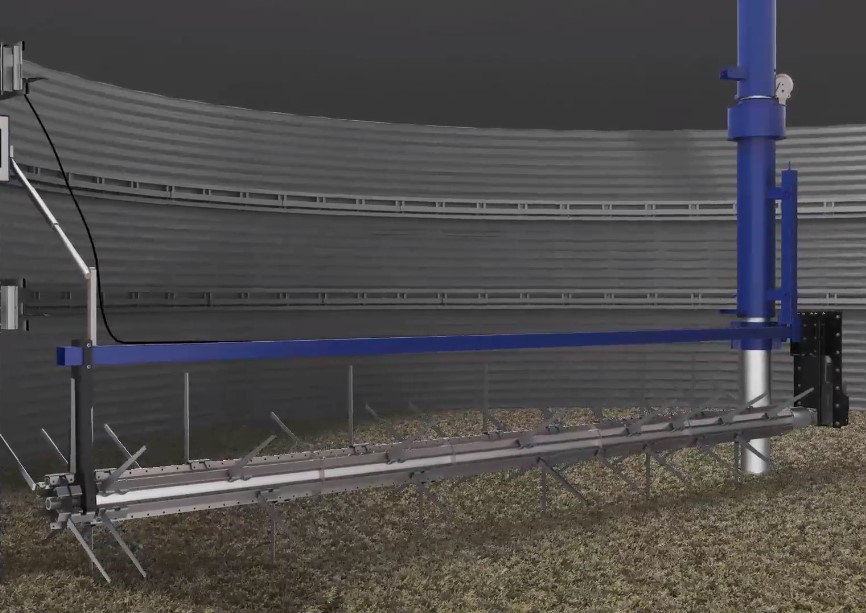

| Automated Spreading, Leveling, & Unloading Auger  Pivoting around the center of the system, the Spreading, Leveling, & Unloading Auger takes the manual process out of loading and unloading your system. As wet biomass is loaded through the loading door, the Spreading, Leveling, & Unloading Auger gently draws material inward, evenly distributing across the drying floor. When ready to unload, the auger is re-engaged to draw dry biomass to the unloading floor chutes. Vertical, directional, speed, & tilt operator controls ensure easy adjustment. Pivoting around the center of the system, the Spreading, Leveling, & Unloading Auger takes the manual process out of loading and unloading your system. As wet biomass is loaded through the loading door, the Spreading, Leveling, & Unloading Auger gently draws material inward, evenly distributing across the drying floor. When ready to unload, the auger is re-engaged to draw dry biomass to the unloading floor chutes. Vertical, directional, speed, & tilt operator controls ensure easy adjustment.

|

| Automated Stirring & Decompaction Rotor  Directly opposite the Spreading & Unloading Auger, the Shivvers Decompaction Rotor gently lifts, levels, and decompresses biomass to enhance air flow ensuring a consistent & uniform drying process. Powered by an electric motor, the Decompaction Rotor features strategically positioned tines that rotate through the hemp bed, loosening and turning biomass as it dries. Mechanized speed and height adjustments accommodate maximum control. This decompaction process facilitates a faster, more efficient drying process while eliminating labor. Directly opposite the Spreading & Unloading Auger, the Shivvers Decompaction Rotor gently lifts, levels, and decompresses biomass to enhance air flow ensuring a consistent & uniform drying process. Powered by an electric motor, the Decompaction Rotor features strategically positioned tines that rotate through the hemp bed, loosening and turning biomass as it dries. Mechanized speed and height adjustments accommodate maximum control. This decompaction process facilitates a faster, more efficient drying process while eliminating labor.

|

It Works Like This:

Step 1:

Freshly harvested hemp is loaded through a specially designed loading door.

Step 2:

The operator engages the Spreading, Leveling, & Unloading Auger to begin drawing biomass inward across the drying floor. The Decompaction Rotor gently lifts & levels biomass around the circumference of the system.

Step 3:

The operator then sets desired temperature & drying specifications on the Shivvers Command Center.

Step 4:

The Command Center activates the Shivvers Heater, warming air in the plenum created by the raised drying floor. The Command Center maintains constant communication with your heater throughout the drying process, automatically adjusting heater settings to match the pre-set drying specifications.

Step 5:

Warmed drying air rises up through the perforated floor, pulling moisture as it ascends through the hemp biomass. Saturated air is exhausted through roof vents.

Step 6:

Periodically throughout the drying process, the Decompaction Rotor can be lowered to the desired depth and engaged to gently turn & loosen settled hemp.

Step 7:

When the desired dehydration level is achieved, the operator engages the unloading auger for hemp to be automatically unloaded through chutes located in the drying floor.

*US Patent No. US 11,796,251 B2