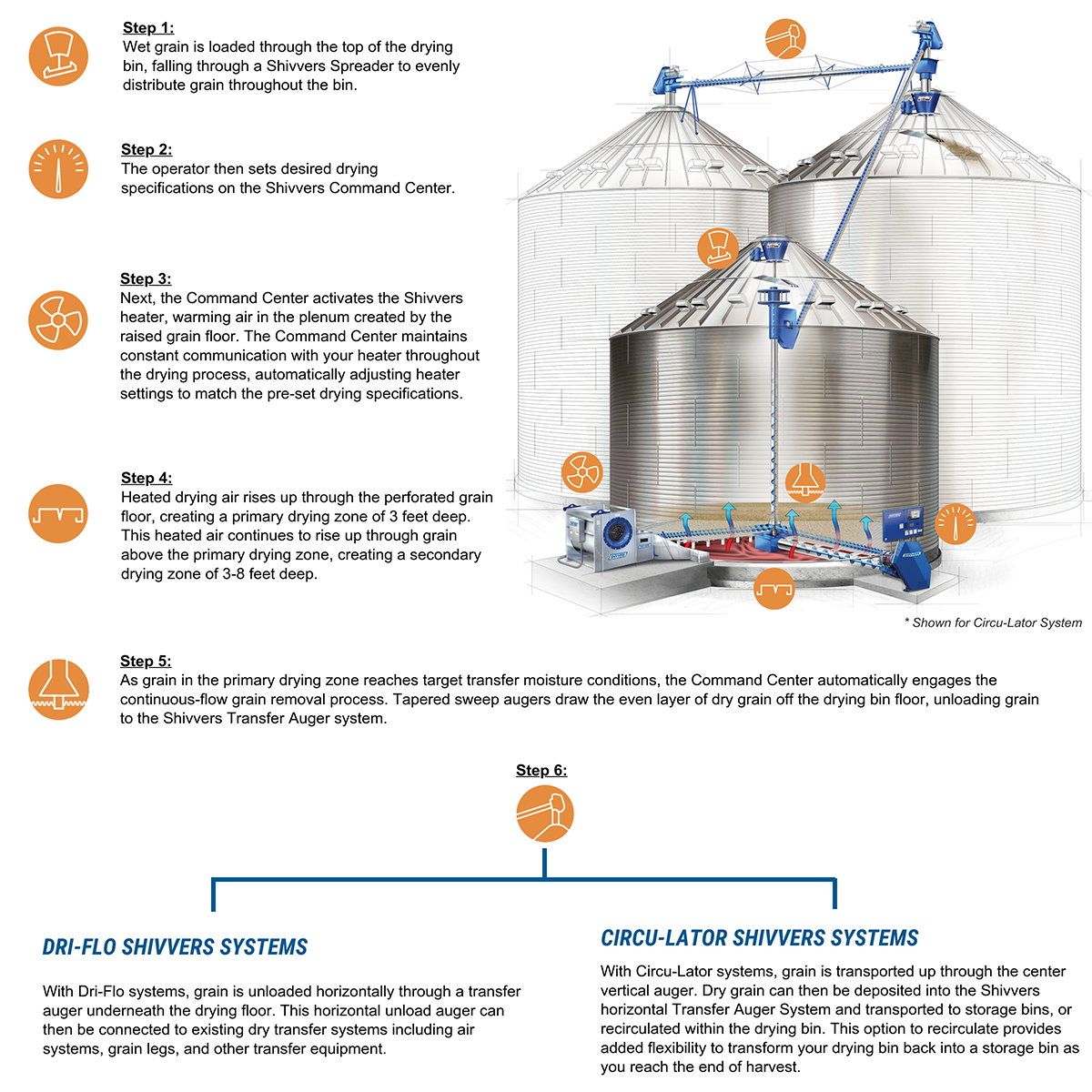

How Shivvers Systems Work

Shivvers Systems are integrated into grain bins to offer a comprehensive solution for drying, handling, and storing grain. Available in 2 main system types, both the Circu-Lator and Dri-Flo Systems utilize the highly efficient Counter-Flow Drying Process.

A complete Shivvers Performance Systems can be broken down into 6 main components:

Command Center- The central computerized control unit that automatically manages the drying process based off of the operators specifications. Command Center- The central computerized control unit that automatically manages the drying process based off of the operators specifications. |  Core Machine- Controls grain flow throughout the drying process, ensuring an even & consistenly dried crop. Core Machine- Controls grain flow throughout the drying process, ensuring an even & consistenly dried crop. |

Spreader- Facilitates level grain loading into the drying bin. Spreader- Facilitates level grain loading into the drying bin. |  Fan/Heater Combination- The heat source & air movement force for the drying process. Fan/Heater Combination- The heat source & air movement force for the drying process. |

Floor- Elevates the grain floor, creating a plenum for the drying system. Strategically designed perforations facilitate maximum air flow. Floor- Elevates the grain floor, creating a plenum for the drying system. Strategically designed perforations facilitate maximum air flow. |  Transfer Augers- Transports dried grain to storage or your desired location. Transfer Augers- Transports dried grain to storage or your desired location. |

Each of these components can be purchased as a package for a complete Shivvers Performance System or individually. So how do they work?

It Works Like This

Your Shivvers system is integrated into a new or existing grain bin, transforming the entire bin into a drying system. This system includes a grain spreader, core machine, computerized Command Center control unit, raised drying floor, heater, and a series of transfer augers to transport dry grain from the drying bin to storage bin(s).

Choosing The Right System: Dri-Flo vs. Circu-Lator

Shivvers Systems are available in 2 core designs: Dri-Flo & Circu-Lator. While both operate using the same Counter-Flow drying process & tapered sweep augers, each system features a unique design to unload grain that has met target drying conditions.

Circu-Lator Systems:

Through the incorporation of a center vertical auger, Circu-Lator Systems offer a unique set of capabilities by allowing both continuous-flow & batch drying operation.

Through the incorporation of a center vertical auger, Circu-Lator Systems offer a unique set of capabilities by allowing both continuous-flow & batch drying operation.

As tapered sweep augers pull an even layer of dried grain toward the center of the bin, the Ciru-Lator uses a center vertical auger to move grain up vertically through the center of the drying bin. Grain can then be continuously carried through the system’s transfer auger system to storage bins, or recirculated within the drying bin. Each Circu-Lator machine also features a horizontal unload auger located under the bin floor for conventional unloading.

The Circu-Lator’s center vertical auger provides 3 distinct benefits:

- Ability to transform your drying bin into a storage bin by recirculating your last batch of dried grain within your drying bin.

- Comprehensive grain drying & storage management without the need for additional transfer equipment, such as grain legs or air systems - the center vertical auger integrates with the Circu-Lator’s overhead transfer auger system to carry dried grain to storage bins.

- An added layer of drying precision, provided by the option to recirculate grain through the drying process.

The Circu-Lator System is perfect for the operator looking for maximum drying precision, ultimate system flexibility, and comprehensive control without the need for additional transfer equipment.

Dri-Flo Systems:

Dri-Flo Systems unload dried grain through a horizontal unload auger located underneath the drying floor and do not feature a vertical unload auger.

Dri-Flo Systems unload dried grain through a horizontal unload auger located underneath the drying floor and do not feature a vertical unload auger.

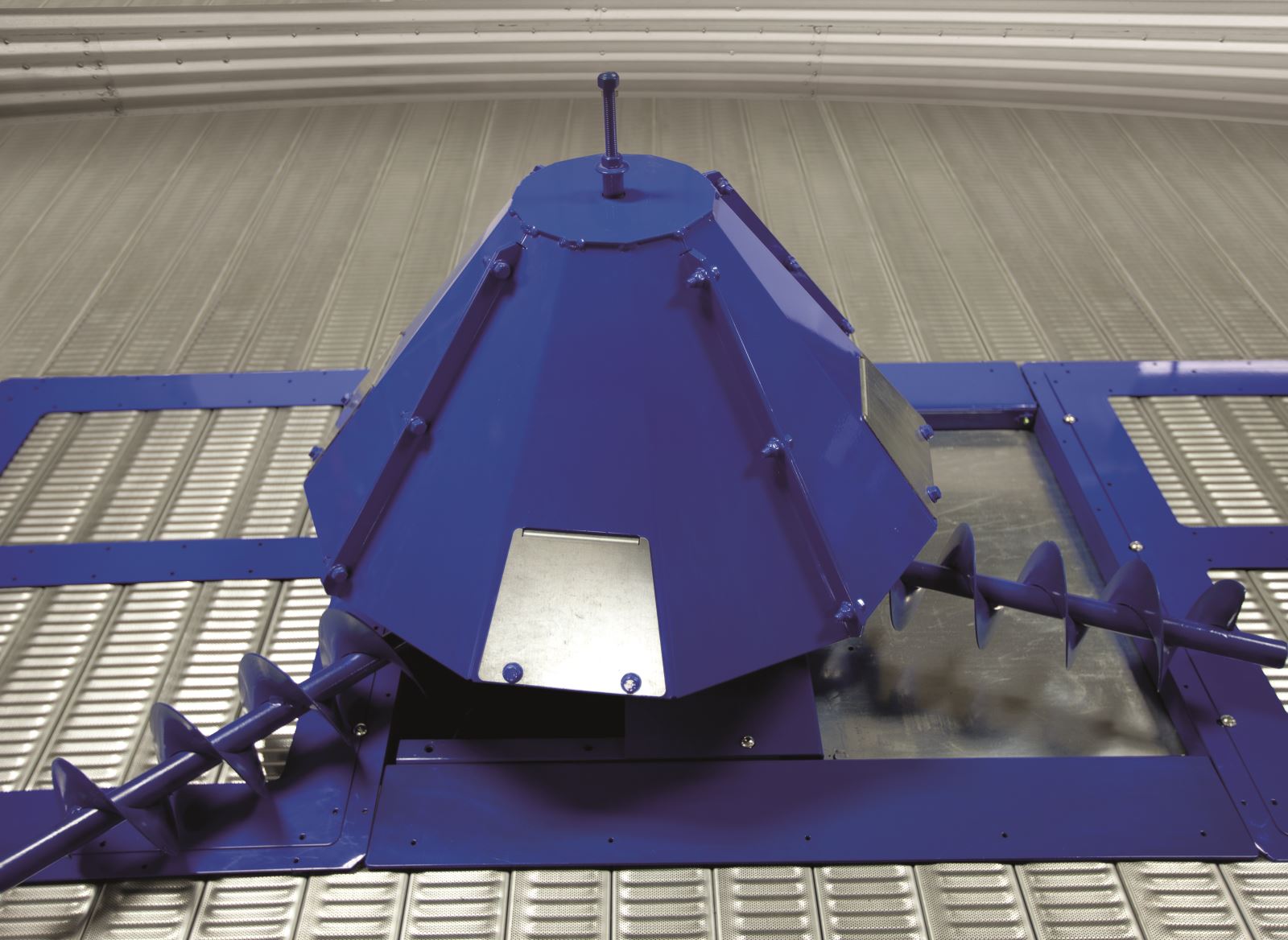

Instead, tapered sweep augers pull an even layer of dried grain toward the Dri-Flo’s center bonnet. The center bonnet accurately meters grain into an underfloor auger for discharge outside of the bin.

The Dri-Flo’s bottom unload design is engineered to facilitate:

- Continuous-flow operation.

- Maximized removal capacities (up to 2500 bph).

- Integration with existing grain transfer systems, such as grain legs or air systems.

The Dri-Flo System is perfect for the operator with an existing dry transfer system, looking for Shivvers Counter-Flow drying precision at maximized removal capacities.