We like to think of our transfer augers as the finishing touch in the drying process, seamlessly transporting grain from the drying bin to your preferred storage location. Each transfer auger is custom designed to fit your operation’s footprint, using the most resilient materials to move hundreds of thousands of bushels each year.

Your Shivvers transfer augers will be based on the type of drying system they’re used with. For example, Circu-Lator systems leverage our Continuous-Flow and Horizontal Transfer Augers to deliver comprehensive, automated grain handling into storage. Dri-Flo systems, meanwhile, feature a bottom unload design augmented with Jumpster or Vertical Unload Augers to facilitate seamless connection to existing dry transfer equipment.

Circu-Lator Transfer Augers

Continuous-Flow Transfer Augers

Continuous-Flow Transfer Augers provide continuous-flow operation capabilities for Circu-Lator systems. The Continuous-Flow Transfer Auger connects to the boot on one side of your drying bin’s interior while the other side is fixed to the top of a nearby storage bin. It is controlled by a Shivvers Command Center that will automatically engage the transfer auger to transport grain when it has met the pre-set transfer moisture conditions.

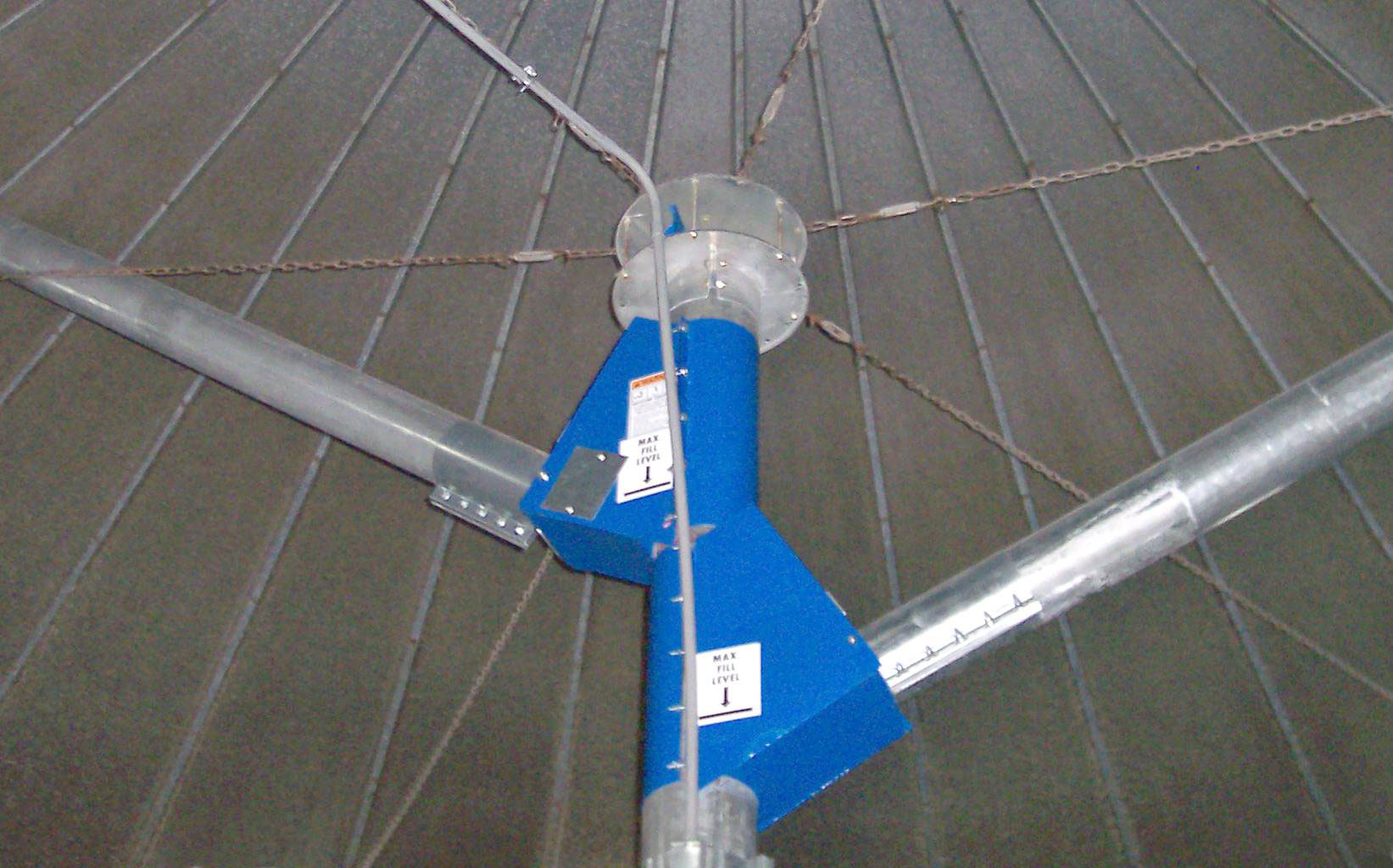

Horizontal Transfer Augers

Horizontal Transfer Augers can then be integrated with the Continuous-Flow Transfer Auger for operators using multiple storage bins. Horizontal Transfer Augers are linked together at the top of each storage bin to expand and synchronize both drying and storage operations based on your needs. Like the Continuous-Flow Transfer Auger, Horizontal Transfer Augers are controlled by your central Shivvers Command Center.

Next, specify the storage bin(s) you’re using and the order in which they’re filled from the command center. As each bin reaches your desired storage capacity, the Command Center automatically begins filling the next one while you can continue to focus on harvest.

Dri-Flo Transfer Auger

Jumpster Unload Auger

As dried grain moves outside drying bins through the Dri-Flo’s unloading system, operators use Shivvers Jumpster Unload Augers for a more seamless connection to their existing dry transfer systems. You can adjust the grain flow as it exits the drying bin at virtually any angle you want. Jumpster Unload Augers are commonly used with existing dry transfer systems and accessories, including grain legs, air systems or other equipment.

Vertical Unload Auger

And for operators wanting to unload grain directly into their trucks, Shivvers also offers a Vertical Unload Auger. Connect the auger directly to your Dri-Flo or Circu-Lator system’s standard horizontal unload auger to lift grain vertically into a cart or hopper.

Double-Run Conveyor

A Double-Run Conveyor provides higher capacity while running at a lower horsepower compared to traditional augers. We’ve designed this conveyor to be gentler on grain, enhancing clean-out by using paddles to move grain through the system.

Double-Run Conveyors are easy to install thanks to a modular design. Components are bolted together and customized to better fit your system. This setup requires fewer support structures for longer applications. Install one today to experience lifelong durability and minimal damage to grain.

These conveyors can replace roof, transfer or dryer takeaway augers to provide a higher capacity with lower horsepower requirements. Replacement is ideal for filling bins in stationary applications, or for a bin unloading system’s incline. The Double-Run Conveyer can be installed at angles ranging from 0° to 60°.