Comprehensive Grain Drying Solutions

| For more than 55 years, Shivvers has been the recognized leader in Counter-Flow Grain Drying Technology. Shivvers offers a complete line of high-volume, high-efficiency, fully automatic grain handling and drying options with capacities of 6,000 to 52,800 bushels per day. The family-owned company got its start when brothers Charles and Gerald Shivvers developed and patented a tapered sweep auger that significantly improved the flow and transfer of grain within a bin compared to conventional augers at the time. | |

As the company grew, Shivvers earned a reputation for quality and value - as well as innovation - and continues to introduce new technologies and components into it's Counter-Flow drying systems that match the growing needs of today's agriculture.

Designed and manufactured in the U.S.A, no other brand - no other drying system - can match the combination of built-in surge capacity, efficiency and flexibility of Shivvers Performance Systems.

A History of Agricultural Innovation

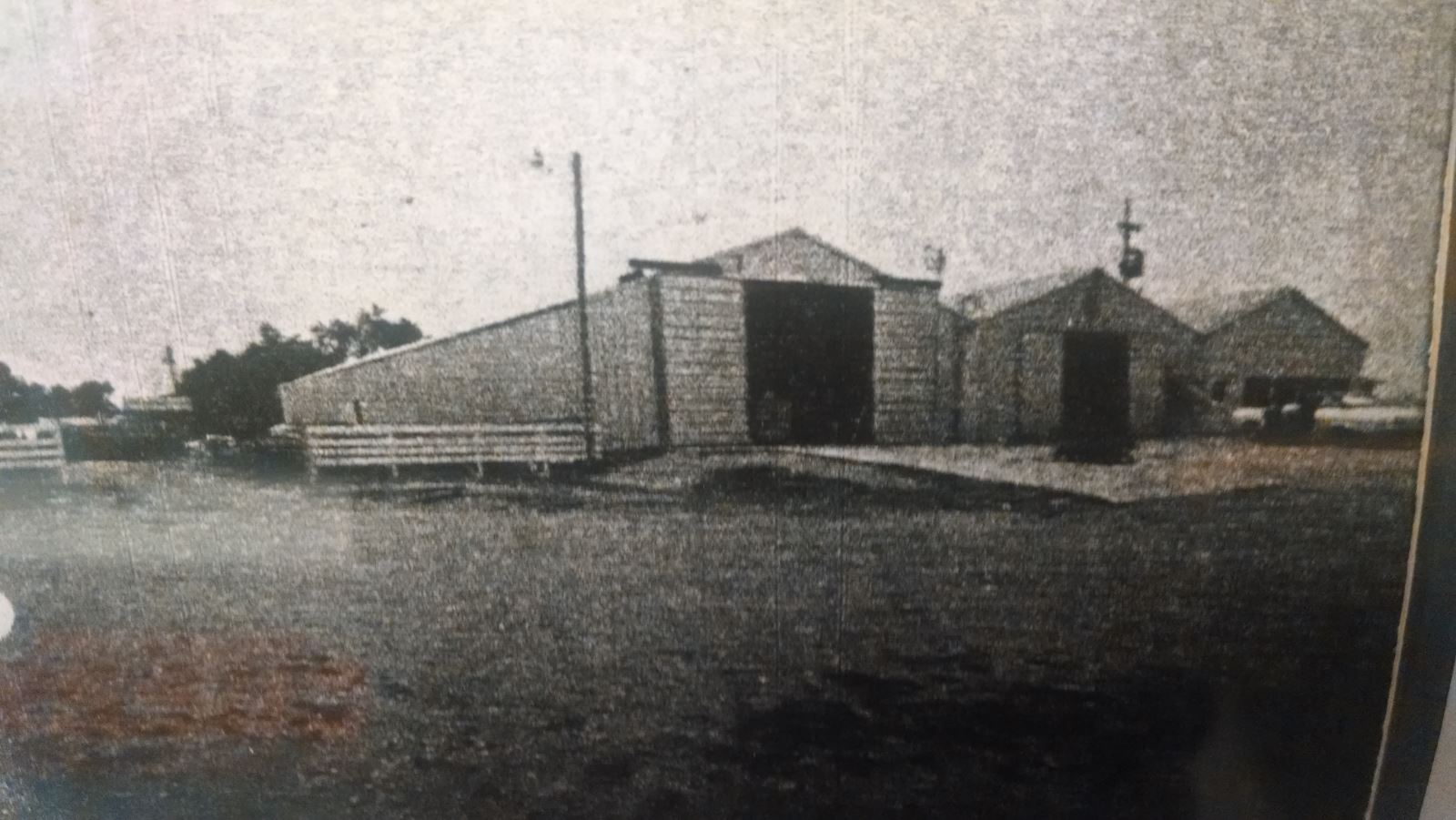

In the mid 1960's Charles Shivvers, aided by his brother Gerald, invented a way to dry grain using a tapered sweep auger. He was able to obtain a patent for his invention and it became the basis for the Shivvers Circu-Lator grain drying system. In 1968 Charles sold both of his farms and bought the Corydon facility. The plant looked very different from what you see today. The office space was less than half the size it is now and the manufacturing plant was a small attached building. At this time, Shivvers was truly a family business. Charles' wife Anita kept the books on a card table that she used for a desk. One of our first employees, Roma Jennings, remembers that the office was usually cold and windy. She sat just inside the front door and whenever anyone came in her papers would be blown all over.

Soon after establishing the factory, Charles asked his son, Carl, to become the Marketing Director. His other son, Steve, was still in high school at the time and he drafted the first blueprints for the Circu-Lator and helped install them in the field.

Soon after establishing the factory, Charles asked his son, Carl, to become the Marketing Director. His other son, Steve, was still in high school at the time and he drafted the first blueprints for the Circu-Lator and helped install them in the field.

The 70's were a great decade for agriculture and Shivvers dryers were a big success. The company expanded and Carl set up a sister company in Illinois. Reflecting the change in the agricultural economy of the 80's, in 1982 the Illinois plant was consolidated into the Corydon facility.

The constant change in the agricultural economy made it obvious that a non-agricultural product needed to be added to the company's line. In the late 1970's, Charles pursued his interest in good coffee and efficient means for drying the beans by marketing his own brand of coffee. In the early 1980's, Steve designed and marketed wood burning stoves. Then, in 1984, the proposal for a zero turn radius lawn mower was made. By 1985 the engineering department designed the first prototype for the Country Clipper ZTR and the lawn mower line was born and continues to be a thriving division of Shivvers.

It was about this same time that long term engineer Don Parkes thought of the idea for the CompuDry, a computerized dryer control that would attach to existing Shivvers grain dryers. This device regulated the drying of grain automatically and had a ready market in Shivvers dryers already in the field. This was the beginning of Shivvers electronics lineup.

Shivvers Mfg., Inc. is still a family owned business with Carl Shivvers as President. We believe Shivvers is successful and able to thrive because of its employees.

Family Based, Everyday People

Part of the appeal of being a Shivvers employee is not just the commitment to quality and service in our finished product, but the sense of history and family that prevails throughout the company. The atmosphere of being part of the family unit and working as a team generates a unified, goal-oriented group, whose whole is greater than its parts. From the first “good morning” to the last “have a good evening”, we are a team dedicated to designing, engineering, manufacturing, and marketing the finest grain drying equipment available; because at the end of your long business day in the fields, you have a family waiting at home for you.

Part of the appeal of being a Shivvers employee is not just the commitment to quality and service in our finished product, but the sense of history and family that prevails throughout the company. The atmosphere of being part of the family unit and working as a team generates a unified, goal-oriented group, whose whole is greater than its parts. From the first “good morning” to the last “have a good evening”, we are a team dedicated to designing, engineering, manufacturing, and marketing the finest grain drying equipment available; because at the end of your long business day in the fields, you have a family waiting at home for you.