Grain loading equipment provides more than an even grain distribution. Besides, we perfected that technology decades ago. Today, our spreaders and grain loaders deliver greater control with the same efficient drying you expect from Shivvers. By carefully adjusting grain depth with state-of-the-art controls, you’ll ensure consistent drying and optimal airflow whatever the capacity.

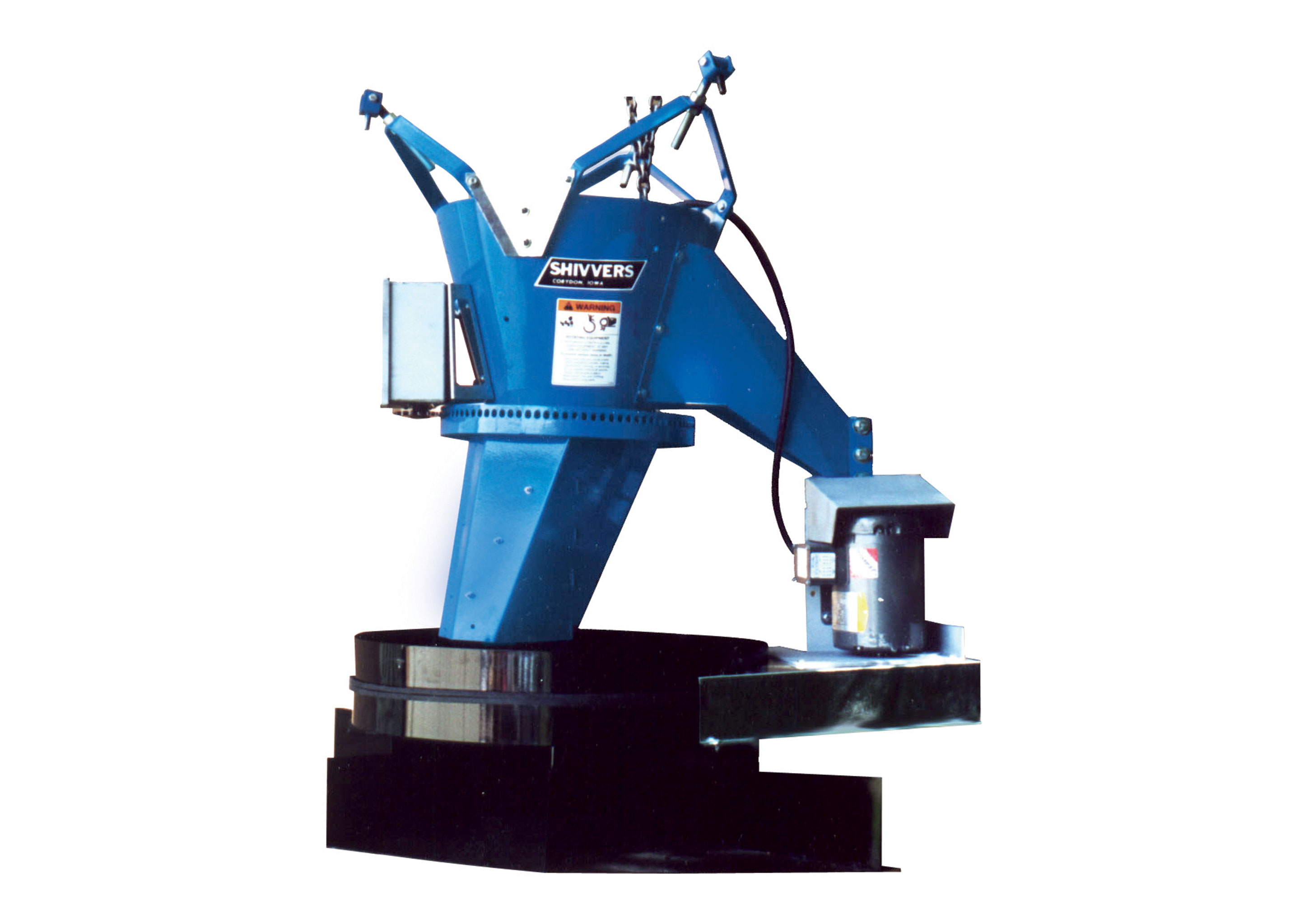

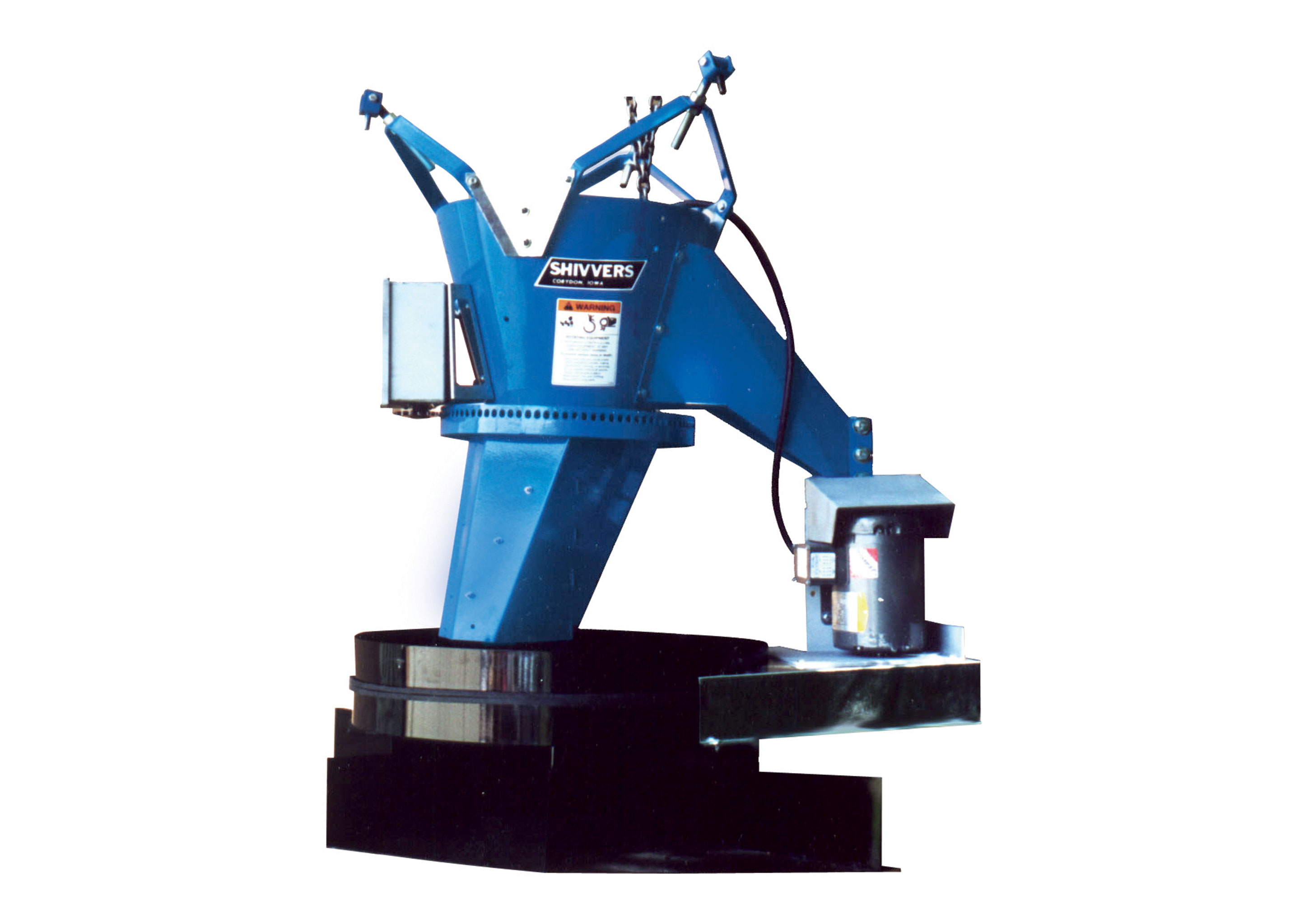

Level-Dry Grain Spreader

The Shivvers Level-Dry grain spreader increases drying capacities anywhere from 30-300% by converting in-bin, continuous-flow dryers into ultra-high-speed drying systems.

Rather than mounting to the top of the bin’s interior, we secure the Level-Dry around a central, adjustable pivot point that can be raised or lowered to match your desired grain depth. As grain enters the bin, the Level-Dry’s hopper funnels it to the leveling auger for spreading. By rotating the auger around the pivot point, we ensure grain is evenly distributed throughout the bin. It’s easy to adjust grain depths at any time during the loading process. If the wet grain develops any dips or low spots, the spreader fills them after each pass to maintain a smooth, uniform surface.

The Level-Dry’s revolutionary design is perfect for those looking for maximized capacities, unmatched efficiency, and unprecedented drying precision.

Controlled-Flow Spreader

The Controlled Flow Spreader facilitates bin-filling capacities of up to 6,000 bushels per hour from any 10 – 13 inch diameter transport auger. With its dual motor system, one drives the diverter valve while the other rotates the spreader pan. Both the pan’s rotation speed and where the grain falls on it can be adjusted independently from the ground. If low spots develop, you can stop the pan rotation to fill in the area in minutes to make the grain bed level again. Such expansive control is perfect for larger operations still looking for precise, from-the-ground filling.

Grain Hog Spreaders

As the standard for a Shivvers Performance System, the Grain Hog Spreader boasts filling capacities ranging from 3,200 to 5,000 bushels per hour, providing a mechanically adjustable spreading solution.

Grain Hog spreaders use a single-speed motor, with different models offering between .5-1.5 horsepower. These spreaders’ available pan sizes accommodate bins 24 to 42 feet in diameter as well as 8 to 12 inch augers. The design also allows you to make additional adjustments to the spreader itself, to ensure a perfectly calibrated spreader to fit your operation’s needs.

While the Grain Hog Spreader is the perfect economical option to distribute grain with Shivvvers’ precision standards, additional capabilities can be achieved with the addition of the Mini Diverter.

Mini Diverter

The Shivvers Mini Diverter mounts above the Grain Hog Spreader, rotating the grain stream for a perfectly centered effect. Rated for augers up to 10 inches in diameter/3,000 bushels per hour, you can add a Mini Diverter to any bin with at least a 28 inch roof opening. No special receptable is needed, and the diverter runs on just 1 amp of 120 VAC power.