Six Shivvers Innovations, Working Together to Create a Better Operation

A complete Shivvers system can be broken down into six core components that work together to deliver a comprehensive drying system. Individual components can be combined with existing equipment, or all together as a complete Shivvers Performance System.

Once you first contact your Shivvers representative, they’ll work with you to figure out what component(s) your drying operation needs to take it to the next level. Better airflow? Higher fuel efficiency? We have a solution to meet every challenge. And whatever the final combination looks like, you’ll have peace of mind it’s tailored to your priorities. Continue below to learn more about our six core drying system components.

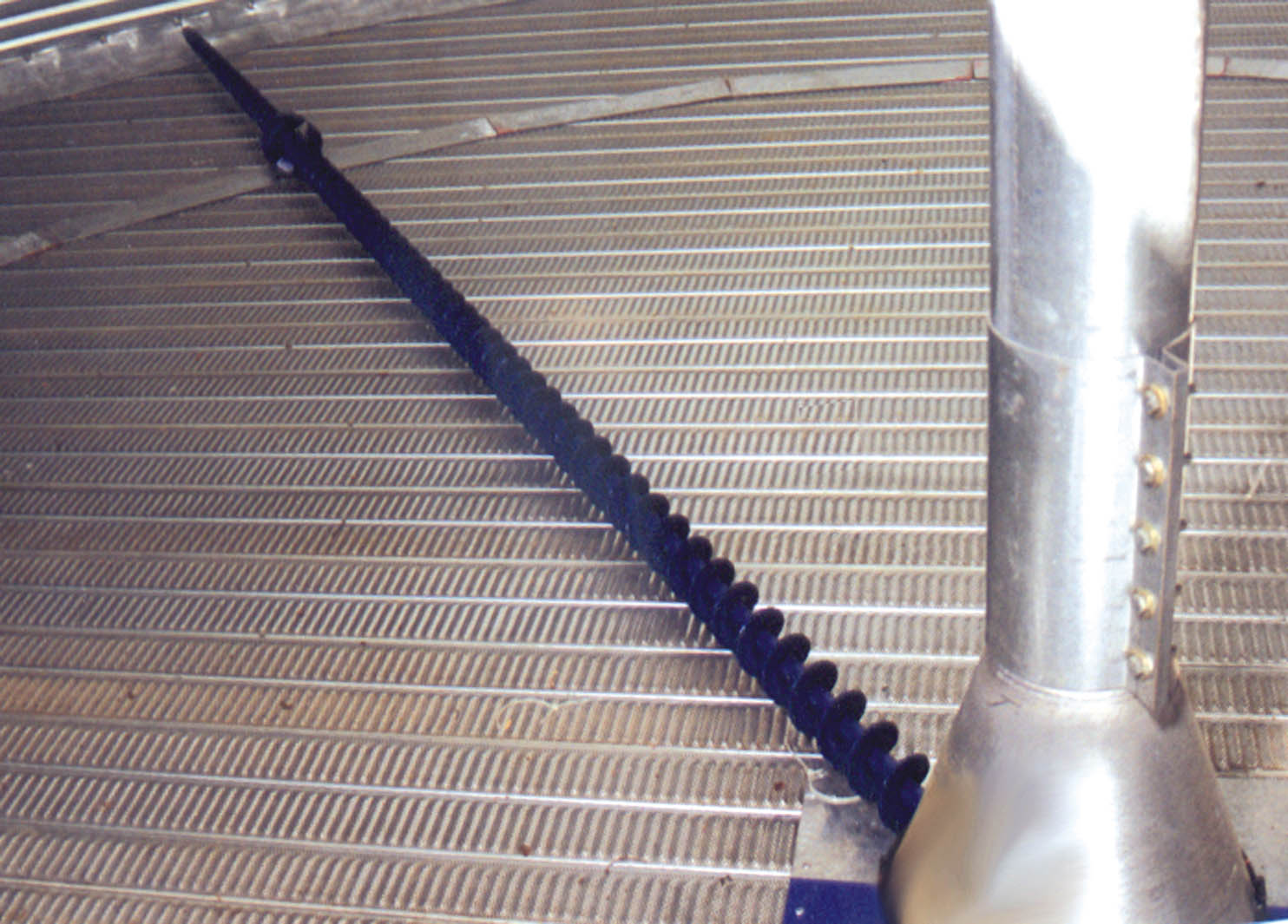

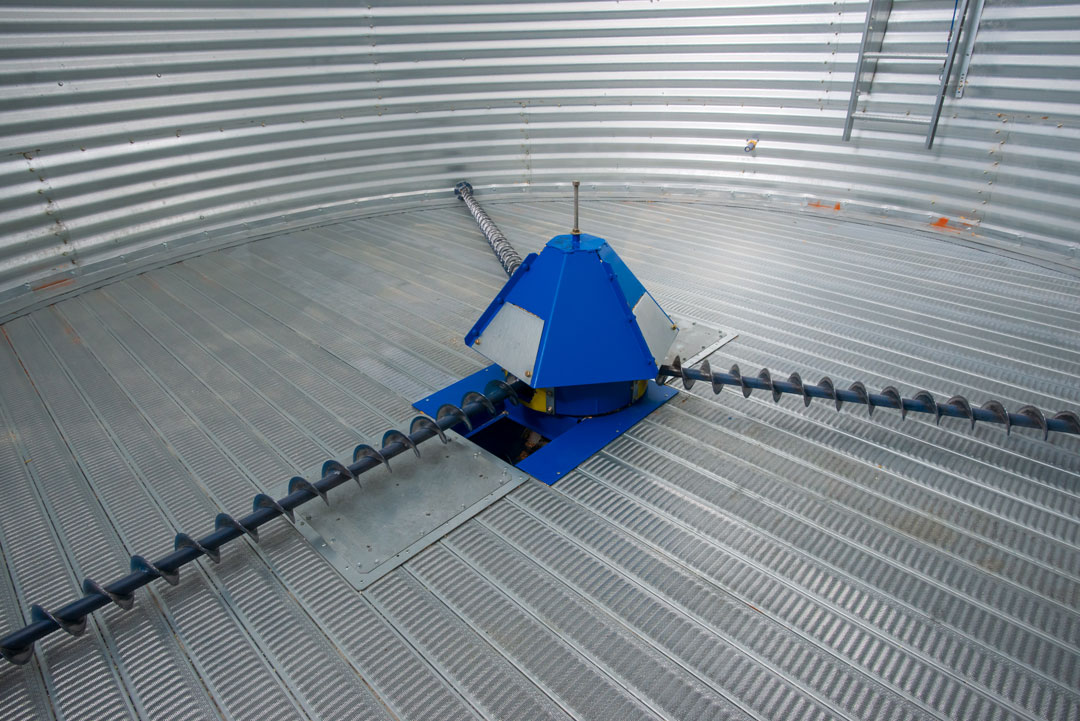

At the ‘Heart’ of Every Shivvers System Is Our Core Machine

This central component controls grain flow across the entire drying process. Purchase your core machine as part of a complete Shivvers Performance System, or as a separate component to pair with existing equipment and a Shivvers Command Center.

Core machines are offered in two main designs: the Dri-Flo or Circu-Lator. Each design is available in several different models to match your bin diameter and drying capacity needs.

Circu-Lator Models

Perfect for operators looking for:

- Optimum drying precision

- Flexible, continuous-flow batch operation

- Maximum storage capabilities

- A comprehensive drying and storage solution without the need for additional transfer equipment

Dri-Flo Models

Perfect for the operator that needs:

- Continuous-flow operation

- Maximized removal capacities (up to 2,200 bph)

- Integration with existing wet transfer systems, such as grain legs or air systems