Create Your Custom Hemp Drying Solution

With more than 55 years of experience perfecting our grain drying systems, Shivvers is proud to offer a line of automated hemp dryers with our industry-leading temperature control technology.

The Shivvers family of hemp drying equipment provides comprehensive solutions including:

- Precise temperature control

- Remote monitoring of the drying operation

- Seamless compatibility with various hemp biomass harvesting methods

- Reduced labor and operating costs

- Superior preservation of crop quality

How Shivvers Hemp Systems Work

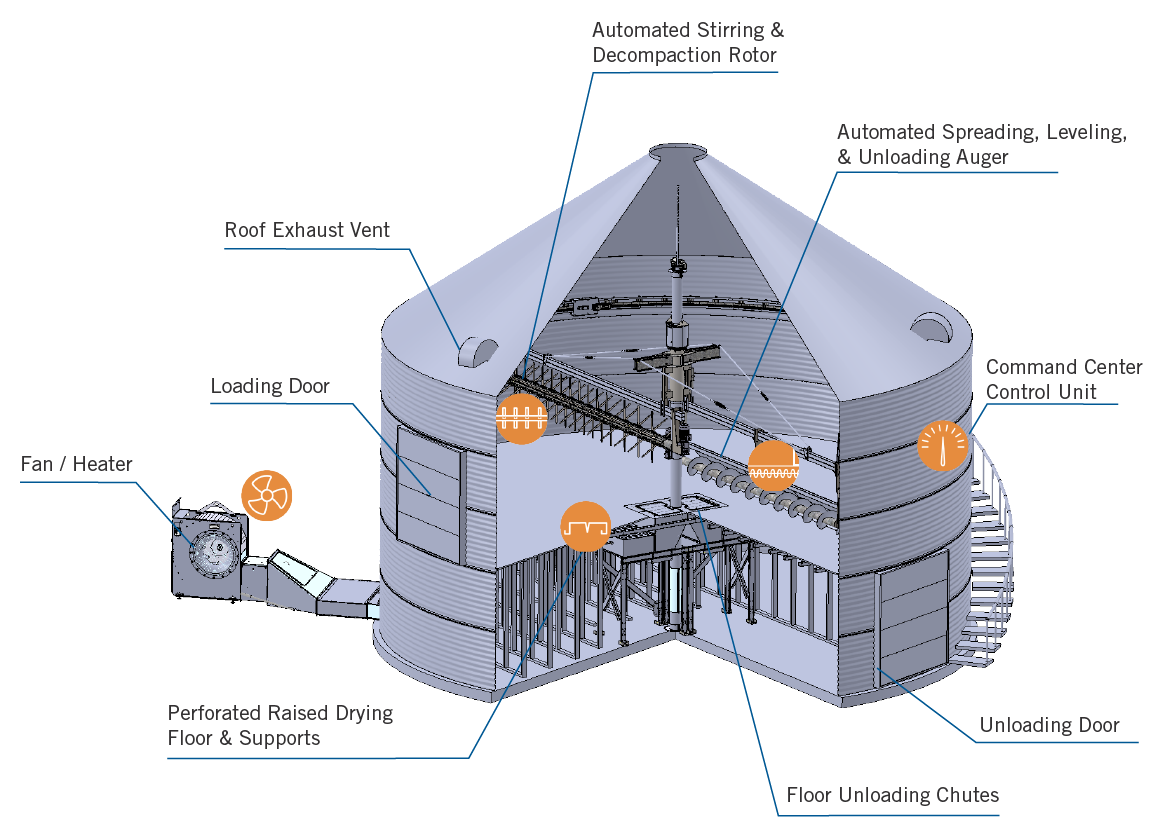

Each Shivvers Hemp Drying System is custom configured and integrated into a grain bin, effectively turning the entire structure into a comprehensive dehydration solution. Depending on your capacity requirements, Shivvers Hemp Drying Systems are available in two sizes with options to fit 24’ and 36’ bin diameters.

System Components:

It Works

Like This:

* US Patent No. US 11,796,251 B2

Load Drying System

Freshly harvested hemp biomass is loaded through a specially designed loading door.

Spread and Level Hemp Biomass

The operator engages the Spreading, Leveling and Unloading Auger to begin drawing hemp biomass inward across the drying floor. The Decompaction Rotor gently lifts & levels hemp biomass around the circumference of the system.

Set Drying Specifications

The operator sets the desired drying temperature on the Shivvers Command Center.

Command Center Controls Drying Process

The Command Center activates the Shivvers Heater to warm the air in the plenum area created by the raised drying floor. The Command Center maintains constant communication with the heater throughout the drying process, automatically adjusting settings to match the pre-set drying specifications.

Heated Air Dries Hemp Biomass

Warmed drying air rises up through the perforated drying floor, removing moisture as it ascends through the hemp biomass. Saturated air is exhausted through roof vents.

Hemp Biomass is Turned and Loosened

Periodically throughout the drying process, the Decompaction Rotor can be lowered to the desired depth and engaged to turn and loosen settled hemp biomass, breaking up any air channels that may have formed.

Unload Drying System

When the desired moisture content is achieved, the operator engages the unloading auger for hemp biomass to be automatically unloaded through the chutes in the drying floor.

Why Do Producers Choose Shivvers?

From planting to harvest, you’re at the mercy of mother nature. But with Shivvers Hemp Drying Systems,

you can take back control. Our commercial hemp drying equipment helps you to:

Increase Shelf Life

Shivvers Hemp Drying Systems help increase shelf life by efficiently removing moisture from the material, which is crucial for preventing mold, mildew and microbial growth. By maintaining optimal drying conditions, Shivvers ensures that your material is dried evenly and thoroughly, reducing the risk of degradation and helping to preserve quality over time. Shivvers Hemp Drying Systems enable growers to achieve a longer shelf life for their crop, thus maximizing its value and marketability.

Harvest On Your Timeline

Harvest confidently and safeguard the profitability of your crops. Reduce the risk of losing your entire crop if it exceeds legal THC limits while allowing your plants to reach their full potential by taking control of your harvest timeline.

Prevent Spoilage

Just a day of exposure to the elements can mean the difference between healthy plants and problems with mold or cannabinoid degradation. Industrial hemp processing equipment like our dryers protects your crop from temperature swings, excess humidity and even UV damage. You know your hemp dryer is an effective solution when it eliminates the risks of leaving plants in the field a day or two longer.

Relieve Bottlenecks

Say goodbye to the bottlenecks of traditional hemp drying methods. Shivvers automated spreading, leveling, stirring and unloading features streamline the drying process to ensure efficiency from start to finish. Upgrade to Shivvers Hemp Drying Systems and break free from the constraints of outdated drying techniques.