Why Do Farmers Choose Shivvers?

| Simple. Because we engineer grain drying systems that let you focus on harvest, with features like: - Counter-Flow Drying Efficiency

- Set-It-And-Forget-It Automated Operation

- Multi-Crop Drying Capability

- Remote Drying & Storage Management Capabilities

- Ability to be Integrated Into New or Existing Bins

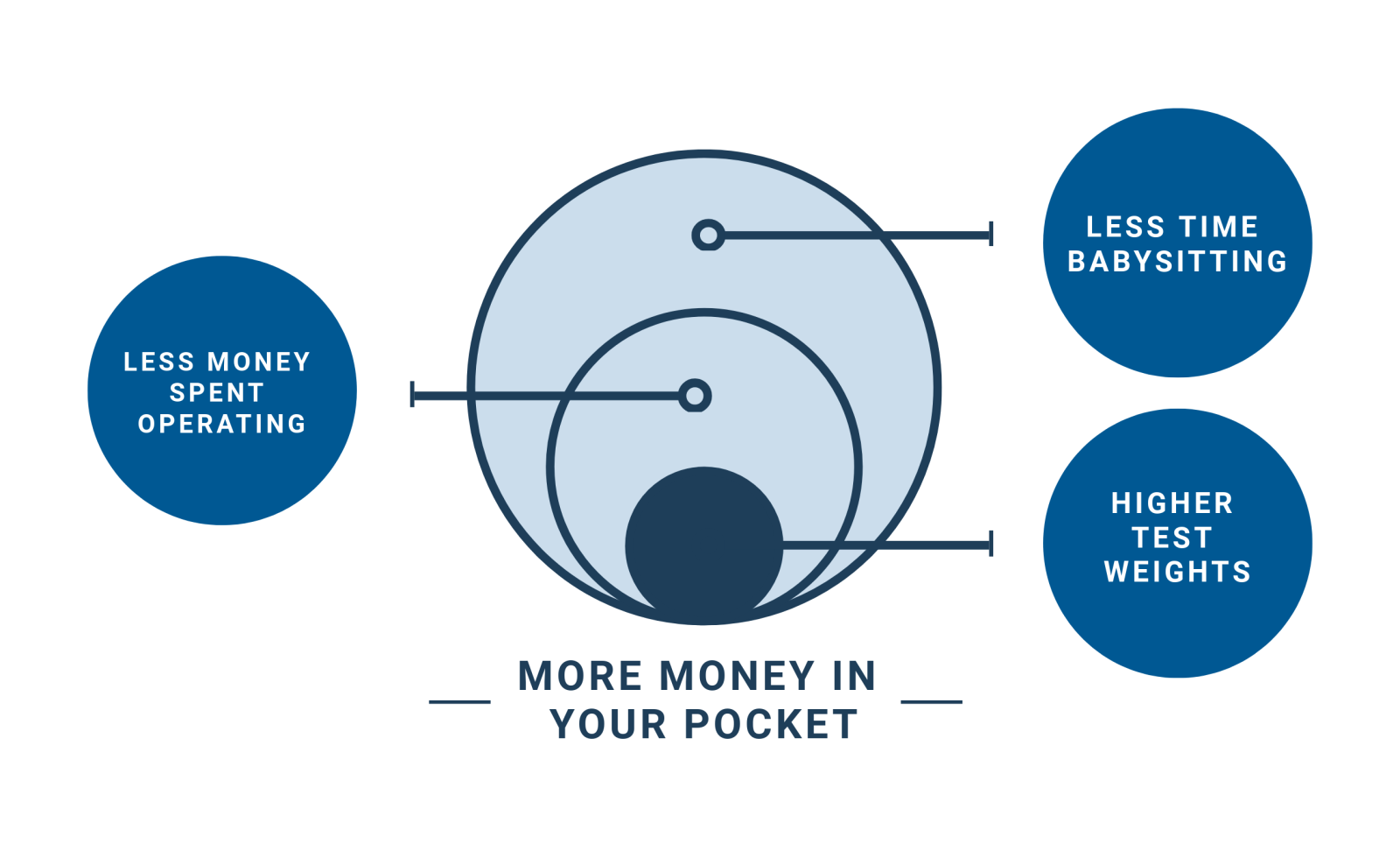

This means less time babysitting, less money spent operating, higher test weights, and more money in your pocket. |

|

Automated Operation - Set-it-and-forget-it Drying Technology

Shivvers defines “No Babysitting” as precision control and automation, achieved through Shivvers computerized Command Center control units. It means having enough surge capacity for the dryer to run 24 hours a day, 7 days a week.  It means you can concentrate your efforts on harvest with the peace of mind that your Command Center is managing every aspect of your grain drying operation.

It means you can concentrate your efforts on harvest with the peace of mind that your Command Center is managing every aspect of your grain drying operation.

Each Shivvers System is controlled by a central, computerized Command Center. The Command Center automatically prevents overdrying by taking readings through a system of sensors and adjusting the plenum heat based on your specifications. When grain has reached your desired transfer moisture level, the Command Center automatically transfers the dried grain to storage in a continuous fashion. If sensors detect grain that has not yet reached preset transfer moisture content, grain is automatically suspended in the drying zone until conditions are met. What does this mean for you? You can focus on harvest.

Unmatched Drying Efficiency

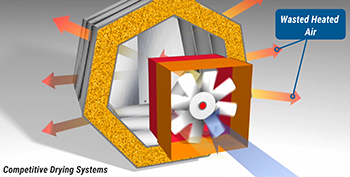

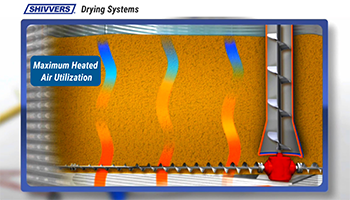

In any drying system, heating air costs money. Shivvers Systems utilize the Counter-Flow Grain Drying Process allowing for a deeper grain depth during the drying process, maximizing efficiency and minimizing operating costs.

| Competitive drying processes employ a grain depth of 12 to 18 inches, meaning heated air is exhausted from the drying process whether it has reached its maximum moisture holding capacity or not. Shivvers Systems operate with 36 to 96 inches of grain depth. This means that the air you paid to heat passes through a much larger volume of grain before being exhausted from the drying process, ensuring it is always used to its maximum moisture-holding capabilities. |

|

For example, in a 48 foot drying tank, heated drying air would pass through an average of 5,792 to 8,688 bushels of grain in a Shivvers System before being exhausted from the top of the bin. Shivvers System’s utilization of larger grain depths result in a much more efficient use of heat & airflow, significantly reducing operation costs.

| Another one of the largest wastes of energy in grain drying occurs from over-drying the grain. Over-drying not only wastes fuel and electricity, but also reduces the resale value of the grain. Shivvers Systems are controlled by a central computerized Command Center that automatically adjusts heat & transfer settings based on the operator’s pre-set transfer moisture specifications. If the Command Center detects a threat that over drying may occur, it automatically adjusts plenum temperatures until proper moisture is reached. |

Combined, the Counter-Flow Drying Process and computerized Command Center precision result in lower operating costs & maximum grain quality. What does this mean for you? More money in your pocket.

Higher Retention Time = Higher Test Weights

Retention time is the duration of time that grain is held in a dryer or drying bin while trying to achieve both targeted moisture content and kernel quality. A Shivvers Performance System, using counter-flow drying, processes the same amount of grain as other drying methods but is able to retain each kernel in the drying bin longer. This not only achieves a more precisely targeted moisture content, it eliminates stress on kernels and uses energy much more efficiently.

Common cross-flow dryers process grain in depths averaging only 12 to 18 inches, taking from ½ hour to two hours for grain to enter and exit the dryer. With the cross-flow drying method, grain is subjected to very high temperatures over a short amount of time and then quickly cooled. The result is more stress cracking. On the other hand, average grain depth using Counter-Flow Drying with a Shivvers Performance System is 3 to 8 feet deep. On average, a single kernel is allowed 12 hours before exiting the drying bin. Since a larger volume of grain receives the heat inputted into the bin, each kernel is dried more slowly as energy is more fully utilized.

The fact that the process is slower does not mean that the dryer is slower or has less capacity. It just means that more grain is in the dryer exposed to drying air for a longer period of time.

The results are dramatically higher test weights with added profit due to less energy usage. Independent test conducted at Michigan State University, Purdue University, and Iowa State University confirm what Shivvers has always known – Counter-Flow Drying is superior to cross-flow drying retaining as much as 2-4 pounds per bushel better test weights.

Multi-Crop Drying Capability

A Shivvers system maintains it's efficiency and delivers excellent capacity at the lower 90º-160º temperatures commonly used with specialty grains as well. This same system has the versatility to dry yellow field corn at 200ºF with high efficiency. These efficiencies, combined with precision control achieved with Shivvers computerized Command Centers allows operators to dry a variety of crops, including:

- Yellow Corn

- Soybeans

- Sunflowers

- Popcorn

- Coffee

- Buckwheat

| - Canola

- Milo

- Rye

- Barley

- Grass

- Hemp Seed

| - Spring Wheat

- Winter Wheat

- White Corn

- White Rice

- Flax

- And More!

|